Barcodes That Turn Everything Into Data!

Purchased, shipped, sold, entered, exited, sterilized, processed, checked, scrapped, watered, fertilized, medicated, etc. the list is endless.

Of the estimated 7 billion barcodes that will be scanned today, most (~90% +) are linear barcodes used in retail applications. These are the same familiar UPC type barcodes that appear on cereal boxes and canned goods that we have seen since the 1970’s. The rest (~10%) are other linear barcodes or 2D barcodes used in newer applications that demand more data in a smaller space. [i]

UPC

Linear barcodes usually contain a single field of data, a product identifier consisting of 7 to 14 numerical digits. These simple barcodes will be read by powerful store scanners designed specifically for the retail type barcodes, namely UPC. However, with the surge in internet shopping, fulfillment centers and the focus on Omni-channel marketing, these barcodes are now being read by a much wider variety of scanner types, including cell phone apps. These general-purpose scanners are less tolerant of poorly printed barcodes and may not be able to read them or not read them easily and accurately. If you are printing UPC barcodes and want to avoid problems then it would be wise to comply with the retail specifications[ii] and make sure you are attaining the minimum quality grade of ISO 2 (ANSI C). This will give you the assurance that you can participate successfully in these newer markets. Doing this simple barcode well is not difficult or expensive, but, today, it is more important that you do it right. Although you may not have heard of any ‘problems’ over the past 40 years, it would be a good idea to check. Retail is changing! You can use a linear barcode verifier like SCANALYST 3 to accomplish this.

Serialized Shipping Container Code

Other linear barcodes may contain more data and it may be alphanumeric. The most frequently used barcode type for this is called Code 128. It has a variable length and can contain multiple data fields. Some of the more common uses are shipping labels, general manufacturing, non-retail product identification, etc. The ability to hold multiple data fields is used to add the product lot code, expiry date, color code, serial number, etc. Code 128 is also used to hold the SSCC (serialized shipping container code), an important data element that is used to link the physical package to a related electronic transaction (EDI) that has purchase and payment information. We are in the traceability era and this barcode is the ‘glue’ that binds physical movement of goods to the underlying data about those goods.

In logistics, giants like FedEx and UPS use linear barcodes to get your packages delivered and to give you precise information on where it is in the process. Automobile manufacturers use linear barcodes to record the serial numbers or the lot code for important parts of their cars. This allows them to have better control in the event of a recall. In the healthcare system, medical devices and pharmaceuticals use multifield linear and 2D codes to protect us from counterfeit, expired or recalled products. All of these newer barcode applications use multiple data fields and more data overall. This means they have many more bars and they need to be wider. It also means that there is additional set of application rules to follow to have a useful barcode. It also means that the data in the barcodes is constantly changing to reflect the new lot codes, serial numbers, etc. This variable data barcode printing is possible using modern digital printing technologies such as found in thermal transfer printers.

DSCSA with ID, Serial, Lot and Expiration Date

Even so, printing the longer, denser linear barcodes can be challenging. And since these applications are ‘mission critical’ the quality you produce should be of a concern. With machine readable data, it is easy to make mistakes and not know it. You need the proper measurement tools, a barcode verifier. This allows you to measure and manage your compliance.

The Time to act is now!

If you have read all this then you realize that doing barcode, especially linear type, is not like it used to be. A wider range of sizes, read by a wider variety of scanners, higher expectation that it will scan easily, and higher risk if it doesn’t!

If you have read all this then you realize that doing barcode, especially linear type, is not like it used to be. A wider range of sizes, read by a wider variety of scanners, higher expectation that it will scan easily, and higher risk if it doesn’t!

- If you are printing barcodes then you should be verifying your barcodes.

- If you have a problem, it may take time to fix it.

- If you are maintaining barcode printers then you should be verifying that the repair resulted in printing good barcodes.

If you already have an old linear verifier laying around somewhere (like the old Symbol (now Zebra), RJS, QuickCheck (now Honeywell) and Axicon) then you should know that it is obsolete. It probably doesn’t do ISO ten scan averaging, is hard to use, impossible to use correctly, doesn’t do any checking of the barcode content for compliance, doesn’t keep records, etc. It is old, can’t do the job and it is time to retire it.

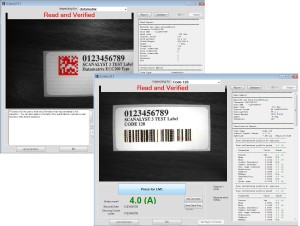

SCANALYST 3 is the barcode verifier that does everything needed for today’s barcode user. Easy to use, portable, built in reporting database, image based, modern design, supported. Whether you need a UPC barcode verifier, a UDI barcode verifier, a DSCSA barcode verifier, or all of them SCANALYST 3 is your choice.

- Upgrades – If you want to add 2D capability in the future, SCANALYST 3 Linear barcode verifier can be upgraded to include all the most popular current 2D codes to protect you from obsolescence. The one below contains the same information as the large linear barcode show earlier.

(01)01234567890500

(01)01234567890500

(21)ser0915

(10)lot1234

(17)062519

- ISO 10 scan average is automatic – Did you know that linear barcode grading requires 10 individual scans to get an average grade? SCANALYST 3 does this for you automatically!

- Checks barcodes for proper GS1 Datastructures

- Imager based – You will not have to learn how to perfect your use of the old stylus/pen contact sensor. SCANALYST 3 takes a high resolution image and does a comprehensive analysis of the barcode in the image. That translates to ‘easy’ and ‘accurate’ compared to the old style verifiers.

- Reports – SCANALYST 3 goes way beyond the old ‘printouts’ . We generate easy to read comprehensive detailed reports that are meaningful. They can be printed on a standard printer.

- EMAIL – The same reports can be emailed to your customers or associates right from the SCANALYST 3 interface.

- Database – All of the individual ISO parameters plus many other characteristics are stored for your future reference. This information can be quite useful in developing best practices or choosing the best printing supplies such as labels, ribbons or ink.

SCANALYT 3 Specifications

To view the complete SCANALYST 3 Specifications, Click here.

SCANALYST 3 Linear Price and Availability

Call us for a Free Barcode Verification analysis and system quote! 614-431-3300

Pricing – $2,795

Our SCANALYST 3 Barcode Verifier is available in many configurations. Click here for a complete list of available options.

Compliance dates for regulated industries

Automotive, defense, electronics, retail, publishing, some parts of life sciences, some parts of healthcare and other sectors of the US economy regulate the quality of their barcodes using industry specifications to outline requirements. Most of these now state clearly ‘you shall comply’. There is a recognition of the importance and little wiggle room left. It costs a lot more to handle products without a scannable barcode and in many cases, it is risky. You might get a lot of returned products, lose a sale and lose a customer. These industries use chargebacks ($50,000!!) to recover costs and reduce problems with bad barcodes and they usually have vendor conformance testing before approving a new supplier. The automotive industry has the AIAG for quality standards on shipping labels and other critical components. The US department of defense has quality standards for their suppliers UID (Unique ID) You can see more at http://www.aiag.org/store/publications/details?ProductCode=B-8

https://www.acq.osd.mil/dpap/UID/attachments/mil-std-130m-20051202.pdf

Note that SCANALYST 3 has a vendor conformance version available to help make the task easier.

On the other hand, barcode applications dictated by government regulations such as the FDA’s DSCSA, UDI and FSMA programs require users to use one or more of the appropriate specs which specify the minimum quality levels necessary for compliance. In other words, it is the law. Non-compliance is not an alternative. The potential risk is too high.

UDI compliance dates – Medical device manufacturers are required to mark their approved products and enter product information into an FDA database. There are several categories of devices and a few different types of UDI marking. Note that this is a global effort. Outside North America, the UDI regulations are usually referred to as the MDR or Medical Device record. You can refer to the current US FDA info at https://www.fda.gov/MedicalDevices/DeviceRegulationandGuidance/UniqueDeviceIdentification/CompliancedatesforUDIRequirements/default.htm

DSCSA compliance dates – Pharma manufacturers and distributors are required to participate in an electronic system to track and trace prescription drugs to insure the integrity of the products and to protect from counterfeit or altered drugs slipping into the pharma supply chain,

FSMA compliance dates – The Food Safety Modernization Act requires changes for most food retailers and gives consumers important tools to determine safe food. https://www.fda.gov/Food/GuidanceRegulation/FSMA/ucm540944.htm

Note that SCANALYST 3 has a healthcare version available to help make barcode compliance in healthcare easier. Also, all requirements under FSMA are covered by SCANALYST 3 as well.

[i] General information on barcode and RFID can be found at http://www.aimglobal.org/

[ii] GS1 General Specifications specify barcode quality and size requirements and can be found at :https://www.gs1.org/sites/default/files/docs/barcodes/GS1_General_Specifications.pdf